During Production Inspection (DPI) is a quality assessment of semi-finished and finished products when the production is completed 20% to 30%. The inspector will check the quality of the semi-finished and finished products according to the product specifications, evaluation methods, quantity of goods, delivery time and other factors given by the customer, and then issue a report.

The mid-term inspection can help you confirm the quality, function, appearance and other factors of the product. It is consistent with your specifications throughout the production process. It also helps to detect any discrepancies as early as possible, thus reducing the risk of delayed delivery.

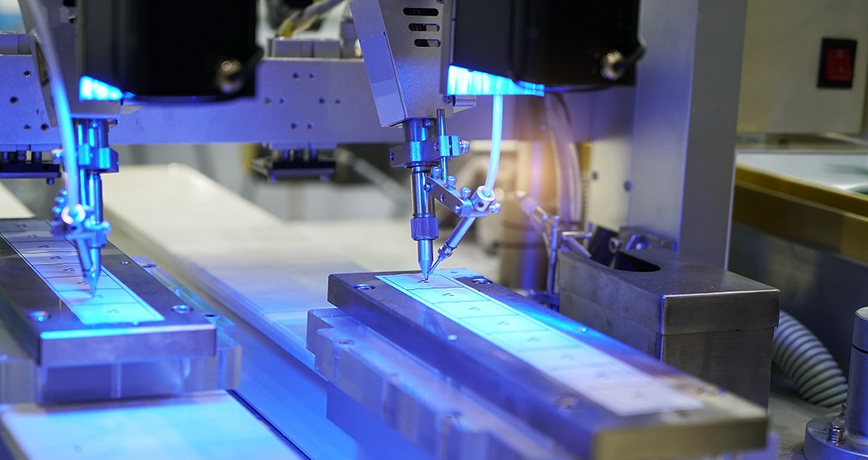

Key points of inspection in production:

A.production situation;

B.Production line assessment and production progress confirmation;

C.Sampling semi-finished products and finished products;

D.Check packaging information and packaging materials;

E.Overall evaluation and recommendations.